Short Lead Time for Expansive Mortar Rock Breaking Chemical - sebacic acid 99.5% – Standard Imp&exp Detail:

sebacic acid

It is a white scaly crystal used to prepare polyamide, polyurethane, alkyd resin, synthetic lubricating oil and lubricating oil additive. Epoxy resin curing agent polyphthalic anhydride, as well as perfume, paint, cosmetics, nylon resin 1010, nylon 610, nylon 810, nylon 9 and other polyamide resin and cold resistant plasticizer DOS, DBS main raw materials

Formula: C10H18O4 HOOC(CH2)8COOH

Synonyms: Sebum

Molecular Weight: 202.25

CAS No.: 111-20-6

Specification:

|

Item |

Super class |

Befined class |

|

|

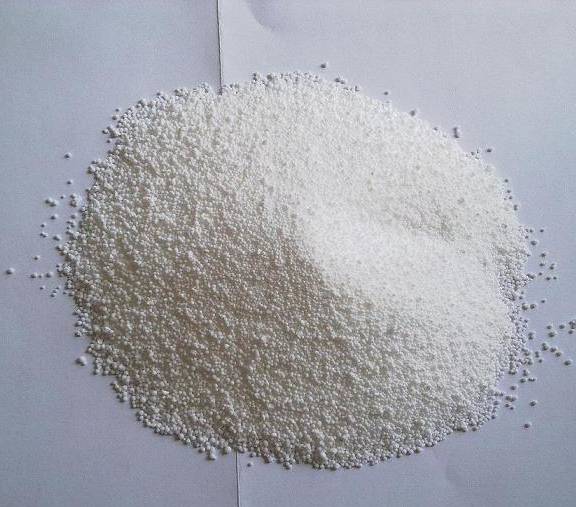

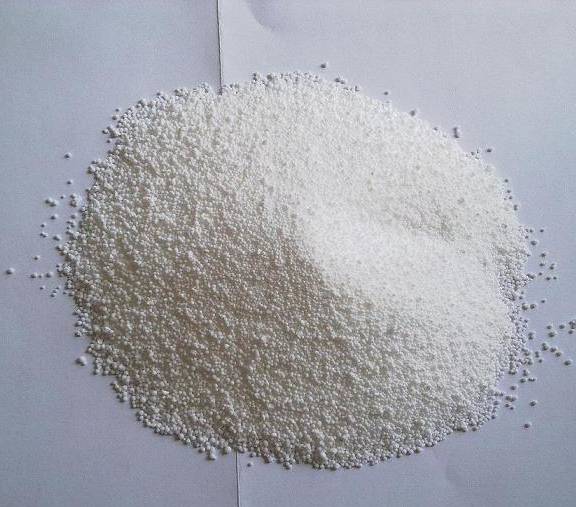

Appearance |

White granular |

White crystal powder |

White granalar |

|

Sebacic Acid Content |

≥99.5 |

≥99.5 |

≥99.5 |

|

Ash(%) |

≤0.03 |

≤0.03 |

≤0.005 |

|

Moisture(%) |

≤0.30 |

≤0.30 |

≤0.10 |

|

Alk Fusion Ch.# |

≤15 |

≤15 |

≤15 |

|

Melting Point Range℃ |

131.0-134.5 |

131.0-134.5 |

131.0-134.5 |

Sebacic acid was first obtained by dry distillation of castor oil and alkali. Later, a synthetic method was developed, and a new route for the production of azelaic acid from petroleum normal paraffin fermentation (see fermentation process) is currently under development. The castor oil alkaline solution commonly used in the industry is in the reaction kettle, and the saponification reaction between castor oil and alkali solution at 100 ° C produces sodium ricinoleate and glycerin. The ricinoleic acid sodium is separated and sulfuric acid is added to form ricinoleic acid, and then alkalized with a base. The reaction temperature is 260-280 ° C, and low pressure or high pressure is used. The reaction produces azelaic acid disodium salt and 2-octanol and hydrogen. Finally, it is neutralized by sulfuric acid, decolorized, crystallized and dried to obtain a pure product with a total yield of over 40%.

Product detail pictures:

Related Product Guide:

Rumford Fireplace Building – Lifespan House | Sodium Fluorosilicate Detergent

SCG displays innovative building materials and technology for better living | Refractory Mortar

Sticking to the principle of "Super Quality, Satisfactory service" ,We are striving to be a good business partner of you for Short Lead Time for Expansive Mortar Rock Breaking Chemical - sebacic acid 99.5% – Standard Imp&exp, The product will supply to all over the world, such as: New York , Surabaya , Mauritius , Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

-

OEM Manufacturer Ssdic/Sodium Dichloroisocyanur...

-

Lowest Price for explosive Expansive Cement - ...

-

Best-Selling High Quality Rock Explosive Demoli...

-

Factory made hot-sale Monosodium Glutamate Fill...

-

OEM China Expansive Mortar Micro Silicon Fume -...

-

OEM/ODM Factory Swimming Pool Chlorine - EDTA ...