OEM manufacturer Monosodium Glutamate Filling Dosing Machine - sebacic acid 99.5% – Standard Imp&exp Detail:

sebacic acid

It is a white scaly crystal used to prepare polyamide, polyurethane, alkyd resin, synthetic lubricating oil and lubricating oil additive. Epoxy resin curing agent polyphthalic anhydride, as well as perfume, paint, cosmetics, nylon resin 1010, nylon 610, nylon 810, nylon 9 and other polyamide resin and cold resistant plasticizer DOS, DBS main raw materials

Formula: C10H18O4 HOOC(CH2)8COOH

Synonyms: Sebum

Molecular Weight: 202.25

CAS No.: 111-20-6

Specification:

|

Item |

Super class |

Befined class |

|

|

Appearance |

White granular |

White crystal powder |

White granalar |

|

Sebacic Acid Content |

≥99.5 |

≥99.5 |

≥99.5 |

|

Ash(%) |

≤0.03 |

≤0.03 |

≤0.005 |

|

Moisture(%) |

≤0.30 |

≤0.30 |

≤0.10 |

|

Alk Fusion Ch.# |

≤15 |

≤15 |

≤15 |

|

Melting Point Range℃ |

131.0-134.5 |

131.0-134.5 |

131.0-134.5 |

Sebacic acid was first obtained by dry distillation of castor oil and alkali. Later, a synthetic method was developed, and a new route for the production of azelaic acid from petroleum normal paraffin fermentation (see fermentation process) is currently under development. The castor oil alkaline solution commonly used in the industry is in the reaction kettle, and the saponification reaction between castor oil and alkali solution at 100 ° C produces sodium ricinoleate and glycerin. The ricinoleic acid sodium is separated and sulfuric acid is added to form ricinoleic acid, and then alkalized with a base. The reaction temperature is 260-280 ° C, and low pressure or high pressure is used. The reaction produces azelaic acid disodium salt and 2-octanol and hydrogen. Finally, it is neutralized by sulfuric acid, decolorized, crystallized and dried to obtain a pure product with a total yield of over 40%.

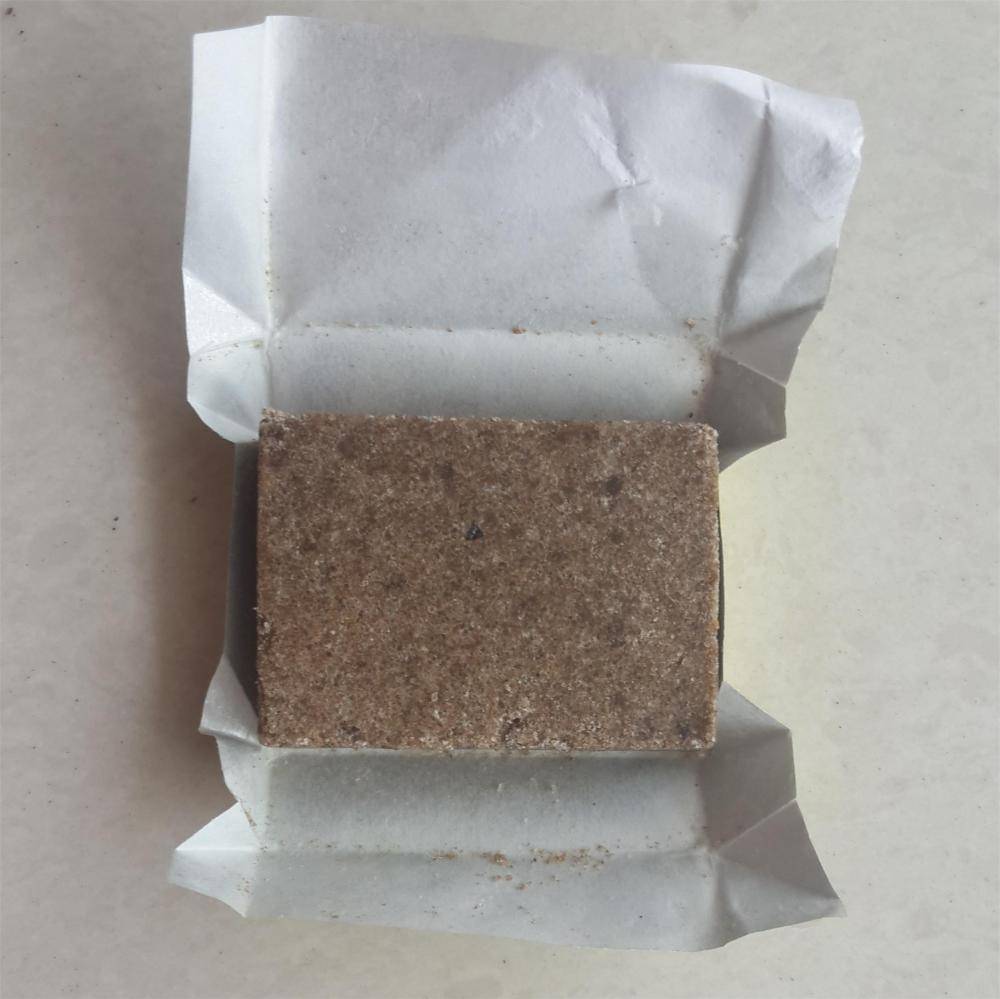

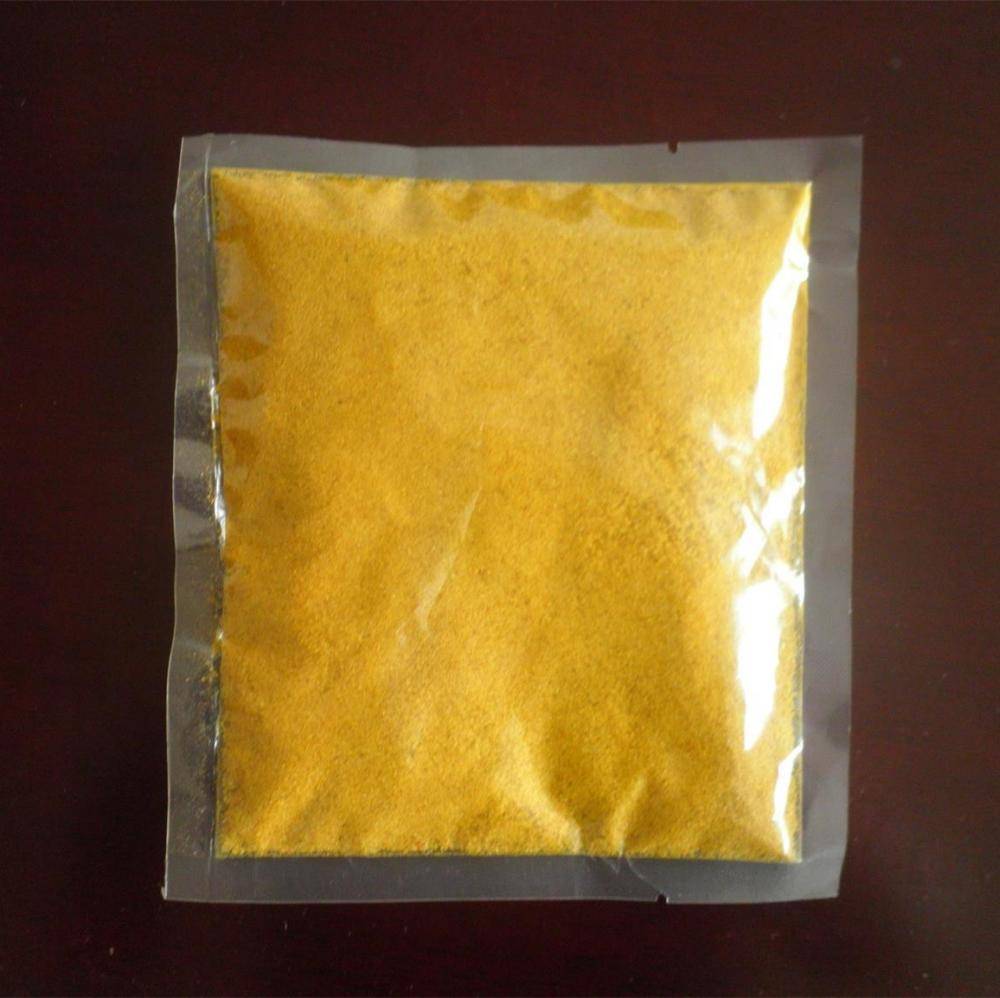

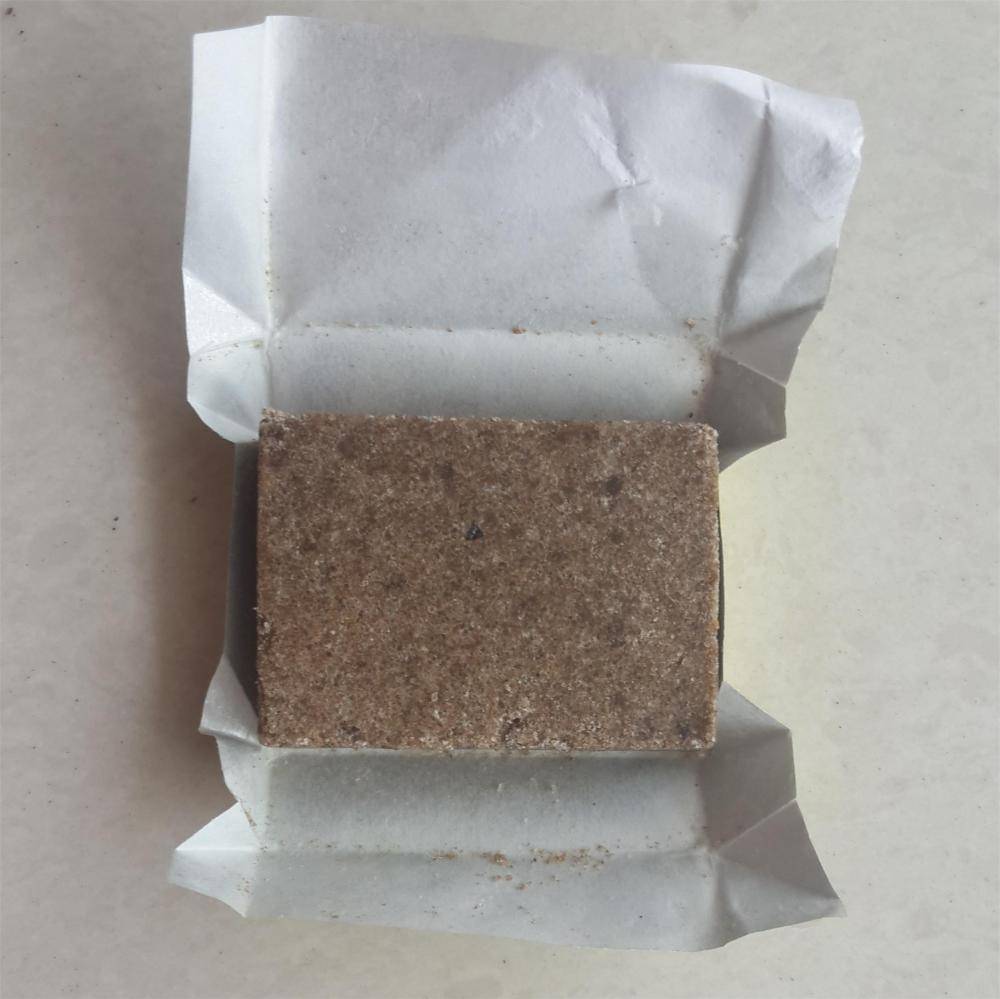

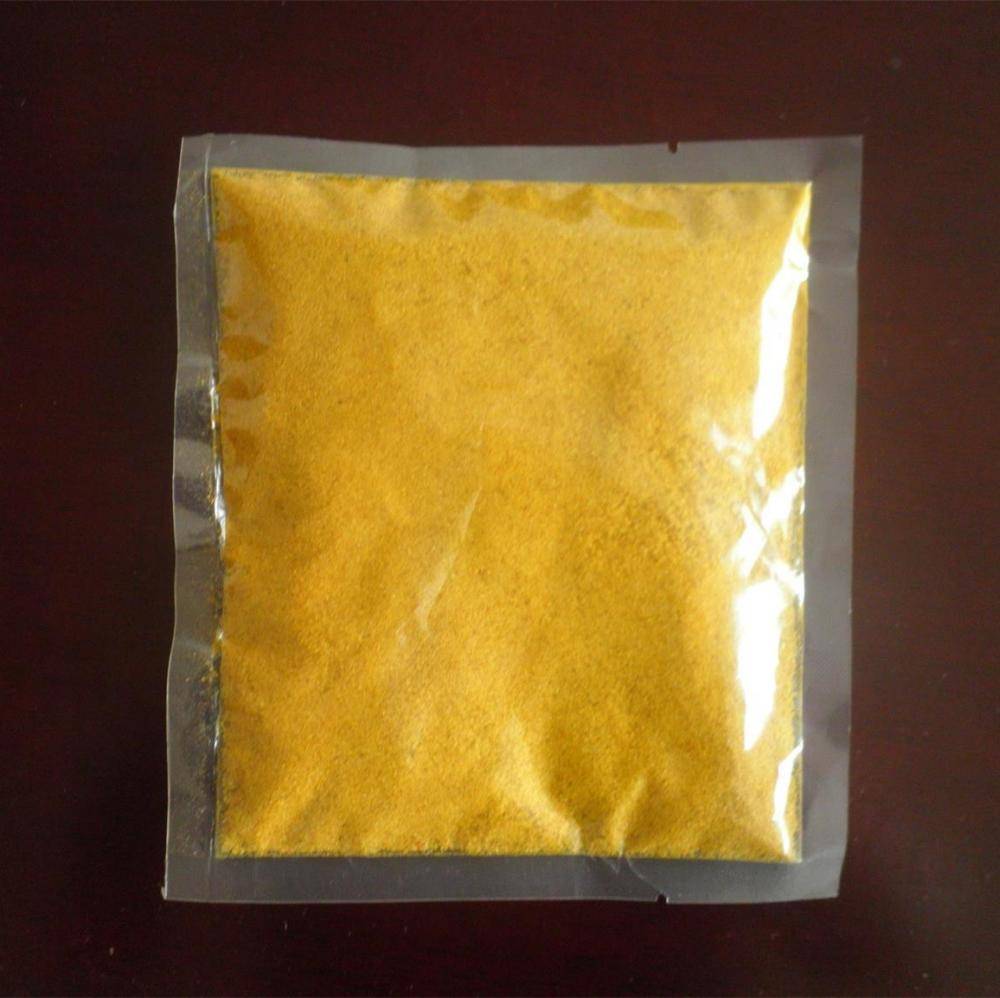

Product detail pictures:

Related Product Guide:

Asia Pacific Data Protection and Cyber Security Guide 2018 – Shifting landscapes across the Asia-Pacific region | Hogan Lovells | Magnesium Chloride White Pellet

VIDEO: You’ve never tasted pizza like they make in Richards Landing! | Refractory Mortar

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for OEM manufacturer Monosodium Glutamate Filling Dosing Machine - sebacic acid 99.5% – Standard Imp&exp, The product will supply to all over the world, such as: Puerto Rico , Egypt , El Salvador , For anyone who is keen on any of our items right after you view our product list, you should definitely feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our merchandise by your self. We're always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

-

Discountable price Magnesium Chloride Flakes - ...

-

Factory Free sample Chicken Tikka Masala - mag...

-

Ordinary Discount High Quality 99% Purity Monos...

-

Discountable price 90% Tcca Swimming Pool Chlor...

-

Wholesale Dealers of Tcca 90% Chlorine Powder -...

-

PriceList for Top Quality China Hsca Cracking A...